Motor oil or engine oil is an oil used for lubrication of various internal combustion engines. The main function is to lubricate moving parts; it also cleans, inhibits corrosion, improvessealing, and cools the engine by carrying heat away from moving parts.[1]

Motor oils are derived from petroleum-based and non-petroleum-synthesized chemical compounds. Motor oils today are mainly blended by using base oils composed ofhydrocarbons, polyalphaolefins (PAO), and polyinternal olefins[2] (PIO), thus organic compounds consisting entirely of carbon and hydrogen. The base oils of some high-performance motor oils contain up to 20 wt.-% of esters.[3]

Contents[hide]

|

Use

Motor oil is a lubricant used in internal combustion engines. These include motor or road vehicles such as cars and motorcycles, heavier vehicles such as buses and commercial vehicles, non-road vehicles such as go-karts, snowmobiles, boats (fixed engine installations and outboards), lawn mowers, large agricultural and construction equipment, locomotives and aircraft and static engines such as electrical generators. In engines, there are parts which move against each other causing friction which wastes otherwise useful power by converting the energy to heat. Contact between moving surfaces also wears away those parts, which could lead to lower efficiency and degradation of the engine. This increases fuel consumption, decreases power output and can, in extreme cases lead to engine failure. Lubricating oil creates a separating film between surfaces of adjacent moving parts to minimize direct contact between them, decreasing heat caused by friction and reducing wear, thus protecting the engine. In use, motor oil transfers heat through convection as it flows through the engine by means of air flow over the surface of the oil pan, an oil cooler and through the build up of oil gases evacuated by the Positive Crankcase Ventilation (PCV) system. In petrol (gasoline) engines, the top piston ring can expose the motor oil to temperatures of 320 °F (160 °C). In diesel engines the top ring can expose the oil to temperatures over 600 °F (315 °C). Motor oils with higher viscosity indices thin less at these higher temperatures.

Coating metal parts with oil also keeps them from being exposed to oxygen, inhibiting oxidation at elevated operating temperatures preventingrust or corrosion. Corrosion inhibitors may also be added to the motor oil. Many motor oils also have detergents and dispersants added to help keep the engine clean and minimize oil sludge build-up. The oil is able to trap soot from combustion in itself, rather than leaving it deposited on the internal surfaces. It is a combination of this, and some singeing that turns used oil black after some running.

Rubbing of metal engine parts inevitably produces some microscopic metallic particles from the wearing of the surfaces. Such particles could circulate in the oil and grind against moving parts, causing wear. Because particles accumulate in the oil, it is typically circulated through anoil filter to remove harmful particles. An oil pump, a vane or gear pump powered by the engine, pumps the oil throughout the engine, including the oil filter. Oil filters can be a full flow or bypass type.

In the crankcase of a vehicle engine, motor oil lubricates rotating or sliding surfaces between the crankshaft journal bearings (main bearings and big-end bearings), and rods connecting the pistons to the crankshaft. The oil collects in an oil pan, or sump, at the bottom of the crankcase. In some small engines such as lawn mower engines, dippers on the bottoms of connecting rods dip into the oil at the bottom and splash it around the crankcase as needed to lubricate parts inside. In modern vehicle engines, the oil pump takes oil from the oil pan and sends it through the oil filter into oil galleries, from which the oil lubricates the main bearings holding the crankshaft up at the main journals and camshaft bearings operating the valves. In typical modern vehicles, oil pressure-fed from the oil galleries to the main bearings enters holes in the main journals of the crankshaft. From these holes in the main journals, the oil moves through passageways inside the crankshaft to exit holes in the rod journals to lubricate the rod bearings and connecting rods. Some simpler designs relied on these rapidly moving parts to splash and lubricate the contacting surfaces between the piston rings and interior surfaces of the cylinders. However, in modern designs, there are also passageways through the rods which carry oil from the rod bearings to the rod-piston connections and lubricate the contacting surfaces between the piston rings and interior surfaces of the cylinders. This oil film also serves as a seal between the piston rings and cylinder walls to separate the combustion chamber in the cylinder head from the crankcase. The oil then drips back down into the oil pan.[4][5]

Non-vehicle motor oils

An example is lubricating oil for 4-stroke or 4-cycle internal combustion engines such as those used in portable electricity generators and "walk behind" lawn mowers. Another example is 2-stroke oil for lubrication of 2-stroke or 2-cycle internal combustion engines found in snow blowers, chain saws, model airplanes, gasoline powered gardening equipment like hedge trimmers, leaf blowers and soil cultivators. Often, these motors are not exposed to as wide service temperature ranges as in vehicles, so these oils may be single viscosity oils.

In small 2-stroke engines, the oil may be pre-mixed with the gasoline or fuel, often in a rich gasoline:oil ratio of 25:1, 40:1 or 50:1, and burned in use along with the gasoline. Larger two-stroke engines used in boats and motorcycles, will have a more economical oil injection system rather than oil pre-mixed into the gasoline. The oil injection system is not used on small engines used in applications like snowblowers and trolling motors as the oil injection system is too expensive for small engines and would take up too much room on the equipment. The oil properties will vary according to the individual needs of these devices. Non-smoking 2-cycle oils are composed of esters or polyglycols. Environmental legislations for leisure marine applications, especially in Europe, enhanced the use of ester-based two cycle oil

Properties

Most motor oils are made from a heavier, thicker petroleum hydrocarbon base stock derived from crude oil, with additives to improve certain properties. The bulk of a typical motor oil consists of hydrocarbons with between 18 and 34 carbon atoms per molecule.[6] One of the most important properties of motor oil in maintaining a lubricating film between moving parts is its viscosity. The viscosity of a liquid can be thought of as its "thickness" or a measure of its resistance to flow. The viscosity must be high enough to maintain a lubricating film, but low enough that the oil can flow around the engine parts under all conditions. The viscosity index is a measure of how much the oil's viscosity changes as temperature changes. A higher viscosity index indicates the viscosity changes less with temperature than a lower viscosity index.

Motor oil must be able to flow adequately at the lowest temperature it is expected to experience in order to minimize metal to metal contact between moving parts upon starting up the engine. The pour point defined first this property of motor oil, as defined by ASTM D97 as "...an index of the lowest temperature of its utility..." for a given application,[7] but the "cold cranking simulator" (CCS, see ASTM D5293-08) and "Mini-Rotary Viscometer" (MRV, see ASTM D3829-02(2007), ASTM D4684-08) are today the properties required in motor oil specs and define the SAE classifications.

Oil is largely composed of hydrocarbons which can burn if ignited. Still another important property of motor oil is its flash point, the lowest temperature at which the oil gives off vapors which can ignite. It is dangerous for the oil in a motor to ignite and burn, so a high flash point is desirable. At a petroleum refinery, fractional distillation separates a motor oil fraction from other crude oil fractions, removing the more volatile components, and therefore increasing the oil's flash point (reducing its tendency to burn).

Another manipulated property of motor oil is its Total Base Number (TBN), which is a measurement of the reserve alkalinity of an oil, meaning its ability to neutralize acids. The resulting quantity is determined as mg KOH/ (gram of lubricant). Analogously, Total Acid Number (TAN) is the measure of a lubricant's acidity. Other tests include zinc, phosphorus, or sulfur content, and testing for excessive foaming.

The NOACK volatility (ASTM D-5800) Test determines the physical evaporation loss of lubricants in high temperature service. A maximum of 15% evaporation loss is allowable to meet API SL and ILSAC GF-3 specifications. Some automotive OEM oil specifications require lower than 10%.

Grades

The Society of Automotive Engineers (SAE) has established a numerical code system for grading motor oils according to their viscosity characteristics. SAE viscosity gradings include the following, from low to high viscosity: 0, 5, 10, 15, 20, 25, 30, 40, 50 or 60. The numbers 0, 5, 10, 15 and 25 are suffixed with the letter W, designating their "winter" (not "weight") or cold-start viscosity, at lower temperature. The number 20 comes with or without a W, depending on whether it is being used to denote a cold or hot viscosity grade. The document SAE J300 defines the viscometrics related to these grades.

Kinematic viscosity is graded by measuring the time it takes for a standard amount of oil to flow through a standard orifice, at standard temperatures. The longer it takes, the higher the viscosity and thus higher SAE code.

Note that the SAE has a separate viscosity rating system for gear, axle, and manual transmission oils, SAE J306, which should not be confused with engine oil viscosity. The higher numbers of a gear oil (e.g. 75W-140) do not mean that it has higher viscosity than an engine oil.

Single-grade

A single-grade engine oil, as defined by SAE J300, cannot use a polymeric Viscosity Index Improver (also referred to as Viscosity Modifier) additive. SAE J300 has established eleven viscosity grades, of which six are considered Winter-grades and given a W designation. The 11 viscosity grades are 0W, 5W, 10W, 15W, 20W, 25W, 20, 30, 40, 50, and 60. These numbers are often referred to as the 'weight' of a motor oil; and single-grade motor oils are often called "straight-weight" oils.

For single winter grade oils, the dynamic viscosity is measured at different cold temperatures, specified in J300 depending on the viscosity grade, in units of mPa·s or the equivalent older non-SI units, centipoise (abbreviated cP), using two different test methods. They are the Cold Cranking Simulator (ASTMD5293) and the Mini-Rotary Viscometer (ASTM D4684). Based on the coldest temperature the oil passes at, that oil is graded as SAE viscosity grade 0W, 5W, 10W, 15W, 20W, or 25W. The lower the viscosity grade, the lower the temperature the oil can pass. For example, if an oil passes at the specifications for 10W and 5W, but fails for 0W, then that oil must be labeled as an SAE 5W. That oil cannot be labeled as either 0W or 10W.

For single non-winter grade oils, the kinematic viscosity is measured at a temperature of 100 °C (212 °F) in units of mm²/s (millimeter squared per second) or the equivalent older non-SI units,Stokes (unit|centistokes]] (abbreviated cSt). Based on the range of viscosity the oil falls in at that temperature, the oil is graded as SAE viscosity grade 20, 30, 40, 50, or 60. In addition, for SAE grades 20, 30, and 40, a minimum viscosity measured at 150 °C (302 °F) and at a high-shear rate is also required. The higher the viscosity, the higher the SAE viscosity grade is.

For some applications, such as when the temperature ranges in use are not very wide, single-grade motor oil is satisfactory; for example, lawn mower engines, industrial applications, and vintage or classic cars.

Multi-grade

The temperature range the oil is exposed to in most vehicles can be wide, ranging from cold temperatures in the winter before the vehicle is started up, to hot operating temperatures when the vehicle is fully warmed up in hot summer weather. A specific oil will have high viscosity when cold and a lower viscosity at the engine's operating temperature. The difference in viscosities for most single-grade oil is too large between the extremes of temperature. To bring the difference in viscosities closer together, special polymer additives called viscosity index improvers, or VIIs are added to the oil. These additives are used to make the oil a multi-grade motor oil, though it is possible to have a multi-grade oil without the use of VIIs. The idea is to cause the multi-grade oil to have the viscosity of the base grade when cold and the viscosity of the second grade when hot. This enables one type of oil to be generally used all year. In fact, when multi-grades were initially developed, they were frequently described as all-season oil. The viscosity of a multi-grade oil still varies logarithmically with temperature, but the slope representing the change is lessened.[8] This slope representing the change with temperature depends on the nature and amount of the additives to the base oil.

The SAE designation for multi-grade oils includes two viscosity grades; for example, 10W-30 designates a common multi-grade oil. The two numbers used are individually defined by SAE J300 for single-grade oils. Therefore, an oil labeled as 10W-30 must pass the SAE J300 viscosity grade requirement for both 10W and 30, and all limitations placed on the viscosity grades (for example, a 10W-30 oil must fail the J300 requirements at 5W). Also, if an oil does not contain any VIIs, and can pass as a multi-grade, that oil can be labelled with either of the two SAE viscosity grades. For example, a very simple multi-grade oil that can be easily made with modern base oils without any VII is a 20W-20. This oil can be labeled as 20W-20, 20W, or 20. Note, if any VIIs are used however, then that oil cannot be labeled as a single grade.

The real-world ability of an oil to crank or pump when cold is potentially diminished soon after it is put into service. The motor oil grade and viscosity to be used in a given vehicle is specified by the manufacturer of the vehicle (although some modern European cars now have no viscosity requirement), but can vary from country to country when climatic or fuel efficiency constraints come into play.

Standards

American Petroleum Institute

The American Petroleum Institute (API) sets minimum for performance standards for lubricants. Motor oil is used for the lubrication, cooling, and cleaning of internal combustion engines. Motor oil may be composed of a lubricant base stock only in the case of non-detergent oil, or a lubricant base stock plus additives to improve the oil's detergency, extreme pressure performance, and ability to inhibit corrosion of engine parts. Lubricant base stocks are categorized into five groups by the API. Group I base stocks are composed of fractionally distilled petroleumwhich is further refined with solvent extraction processes to improve certain properties such as oxidation resistance and to remove wax. Group II base stocks are composed of fractionally distilled petroleum that has been hydrocracked to further refine and purify it. Group III base stocks have similar characteristics to Group II base stocks, except that Group III base stocks have higher viscosity indexes. Group III base stocks are produced by further hydrocracking of Group II base stocks, or of hydroisomerized slack wax, (a byproduct of the dewaxing process). Group IV base stock are polyalphaolefins (PAOs). Group V is a catch-all group for any base stock not described by Groups I to IV. Examples of group V base stocks include polyol esters, polyalkylene glycols (PAG oils), and perfluoropolyalkylethers (PFPAEs). Groups I and II are commonly referred to as mineral oils, group III is typically referred to as synthetic (except in Germany and Japan, where they must not be called synthetic) and group IV is a synthetic oil. Group V base oils are so diverse that there is no catch-all description.

The API service classes[9] have two general classifications: S for "service/spark ignition" (typical passenger cars and light trucks usinggasoline engines), and C for "commercial/compression ignition" (typical diesel equipment). Engine oil which has been tested and meets the API standards may display the API Service Symbol (also known as the "Donut") with the service designation on containers sold to oil users.[9]

The API oil classification structure has eliminated specific support for wet-clutch motorcycle applications in their descriptors, and API SJ and newer oils are referred to be specific to automobile and light truck use. Accordingly, motorcycle oils are subject to their own unique standards.

The latest API service standard designation is SN for gasoline automobile and light-truck engines. The SN standard refers to a group of laboratory and engine tests, including the latest series for control of high-temperature deposits. Current API service categories include SN,SM, SL and SJ for gasoline engines. All previous service designations are obsolete, although motorcycle oils commonly still use the SF/SG standard.

All the current gasoline categories (including the obsolete SH), have placed limitations on the phosphorus content for certain SAE viscosity grades (the xW-20, xW-30) due to the chemical poisoning that phosphorus has on catalytic converters. Phosphorus is a key anti-wear component in motor oil and is usually found in motor oil in the form of Zinc dithiophosphate. Each new API category has placed successively lower phosphorus and zinc limits, and thus has created a controversial issue obsolescing oils needed for older engines, especially engines with sliding (flat/cleave) tappets. API, and ILSAC, which represents most of the worlds major automobile/engine manufactures, states API SM/ILSAC GF-4 is fully backwards compatible, and it is noted that one of the engine tests required for API SM, the Sequence IVA, is a sliding tappet design to test specifically for cam wear protection. However, not everyone is in agreement with backwards compatibility, and in addition, there are special situations, such as "performance" engines or fully race built engines, where the engine protection requirements are above and beyond API/ILSAC requirements. Because of this, there are specialty oils out in the market place with higher than API allowed phosphorus levels. Most engines built before 1985 have the flat/cleave bearing style systems of construction, which is sensitive to reducing zinc and phosphorus. Example; in API SG rated oils, this was at the 1200-1300 ppm level for zincs and phosphorus, where the current SM is under 600 ppm. This reduction in anti-wear chemicals in oil has caused pre-mature failures of camshafts and other high pressure bearings in many older automobiles and has been blamed for pre-mature failure of the oil pump drive/cam position sensor gear that is meshed with camshaft gear in some modern engines.

There are six diesel engine service designations which are current: CJ-4, CI-4, CH-4, CG-4, CF-2, and CF. Some manufacturers continue to use obsolete designations such as CC for small or stationary diesel engines. In addition, API created a separated CI-4 PLUS designation in conjunction with CJ-4 and CI-4 for oils that meet certain extra requirements, and this marking is located in the lower portion of the API Service Symbol "Donut".

It is possible for an oil to conform to both the gasoline and diesel standards. In fact, it is the norm for all diesel rated engine oils to carry the "corresponding" gasoline specification. For example, API CJ-4 will almost always list either SL or SM, API CI-4 with SL, API CH-4 with SJ, and so on.

ILSAC

The International Lubricant Standardization and Approval Committee (ILSAC) also has standards for motor oil. Introduced in 2004, GF-4[10]applies to SAE 0W-20, 5W-20, 0W-30, 5W-30, and 10W-30 viscosity grade oils. In general, ILSAC works with API in creating the newest gasoline oil specification, with ILSAC adding an extra requirement of fuel economy testing to their specification. For GF-4, a Sequence VIB Fuel Economy Test (ASTM D6837) is required that is not required in API service category SM.

A key new test for GF-4, which is also required for API SM, is the Sequence IIIG, which involves running a 3.8 L (232 in³), GM 3.8 L V-6 at 125 hp (93 kW), 3,600 rpm, and 150 °C (300 °F) oil temperature for 100 hours. These are much more severe conditions than any API-specified oil was designed for: cars which typically push their oil temperature consistently above 100 °C (212 °F) are most turbochargedengines, along with most engines of European or Japanese origin, particularly small capacity, high power output.

The IIIG test is about 50% more difficult[11] than the previous IIIF test, used in GF-3 and API SL oils. Engine oils bearing the API starburst symbol since 2005 are ILSAC GF-4 compliant.[12]

To help consumers recognize that an oil meets the ILSAC requirements, API developed a "starburst" certification mark.

A new set of specifications, GF-5,[13] took effect in October 2010. The industry has one year to convert their oils to GF-5 and in September 2011, ILSAC will no longer offer licensing for GF-4.

ACEA

The ACEA (Association des Constructeurs Européens d'Automobiles) performance/quality classifications A3/A5 tests used in Europe are arguably more stringent than the API and ILSAC standards. CEC (The Co-ordinating European Council) is the development body for fuel and lubricant testing in Europe and beyond, setting the standards via their European Industry groups; ACEA, ATIEL, ATC and CONCAWE.

Lubrizol, a supplier of additives to nearly all motor oil companies, hosts a Relative Performance Tool which directly compares the manufacturer and industry specs. Differences in their performance is apparent in the form of interactive spider graphs, which both expert and novice can appreciate. http://sas-origin.onstreammedia.com/origin/lubrizol/EOACEA2009/RPTOOL2010Dep/rp/pc/index.html

JASO

The Japanese Automotive Standards Organization (JASO) has created their own set of performance and quality standards for petrol engines of Japanese origin.

For 4-stroke gasoline engines, the JASO T904 standard is used, and is particularly relevant to motorcycle engines. The JASO T904-MA and MA2 standards are designed to distinguish oils that are approved for wet clutch use, and the JASO T904-MB standard is not suitable for wet clutch use.

For 2-stroke gasoline engines, the JASO M345 (FA, FB, FC) standard is used, and this refers particularly to low ash, lubricity, detergency, low smoke and exhaust blocking.

These standards, especially JASO-MA and JASO-FC, are designed to address oil-requirement issues not addressed by the API service categories.

OEM standards divergence

By the early 1990s, many of the European original equipment manufacturer (OEM) car manufacturers resigned on the lacklustre direction of the American API oil standards as it did not perform to the needs of a motor oil to be used in their motors and seriously lagged in development of the previous generations. As a result many leading European motor manufacturers created and developed their own "OEM" oil standards which were no longer directly compatible with the plain API. (Note that the ACEA class of standards is co-developped with all European engine makers to better suit the legislative and techical needs, thus ACEA specification on the back label completely or nearly conforms to many OEM specifications.) In recent years similar happened in the North American diesel engine market in the high performance segment, with names such as Caterpillar, John Deere, Mack, Cummins, Ford appearing on the back of the oil cans in lists of certifications. It is irony that the standard "API C" means "Commercial", and yet it failed to fullfill the needs of the main commercial engine producers.

Some of the of widely used OEM standards are the VW500.**, VW505.** series from Volkswagen Group, and the MB228.* and MB229.** from Mercedes-Benz. Other European OEM standards are from General Motors (dexos), the Ford "WSS" standards, BMW Special Oils and BMW Longlife standards, Porsche, and the PSA Group of Peugeot and Citroën. Prior to the development of the dexos standard, General Motors used the 4718M standard that is used for high-performance engines, a standard that is used in North America for selected North American performance engines, with a "Use Mobil 1 only" sticker was usually placed on those cars.

Fundamental weakness of the generic standards always was that it only served as an assurance of a given minimal performance of the lubricant. Never there was any additional specification that would demand some key parameters to be for example 30% better, as a basis for a future specification. Recently (since 1973, actually) oils which significantly ouperform the minimum standard of the current generation are available, but the only thing which differentiates them is the statement of the manufacturer. In the same way product which barely passed the certification can also claim how great it is. Users were never given any chance to be able to differentiate between those two, other than serious study of the topic (tribology, physics, chemistry, mechanics), roughly equivalent to an university course, followed by examining the manufacturer stated physical properties - if the manufacturer decides to disclose those!

More recently, "extended drain", "BMW longlife" and similar oils have arisen, whereby, taking Volkswagen Group vehicles, a petrol engine can now go up to 2 years or 30,000 km (~18,600 mi), and a diesel engine can go up to 2 years or 50,000 km (~31,000 mi) - before requiring an oil change. Volkswagen (504.00), BMW, GM, Mercedes and PSA all have their own similar longlife oil standards. (In case of MB certified oils, the standard applies to oils used in trucks and personal cars alike, so every Mercedes engine was expected to use the same oil, while other small car makers were satisfied with the generic - and thus least performing lubricants available and catched up recently when the legislation from the European Council mandated them to improve fuel consumption and improve emissions.) This should be not surprising as Mercedes was among the first to differentiate oils according to longevity (1980's to 1990). In personal vehicles is a general oil change interval given by oil specification: 228.1 - 15000 km, 228.3 - 30000 km, 228.5 - 45000 km. (Similar rule applies to the MB 229.xx) Oil certified for the longest change interval also had the best antioxidative properties and stability. Certain BP Vanellus oil certified for MB228.5 standard had sulfated ash content around 2%, thus providing superior piston ring protection as a side-effect. Such oils were originally marketed for heavy trucking use (100000 miles change interval) and other "long life" oils are likely to be of similar grade. [14] The North American habit of having oil changed in the engine every 3000 miles has its roots if past far ago, when the API SC, CB oils were the norm. Those had reserve alkalinity and buffering ability only sourced from the bulk mass of the fresh base stock and offered very, very little in terms of surface protection in corrorsion or mechanical resistance. With better lubricants in the beginning of the 1980's, in europe longer service intervals became the norm, with 10000km in standard car use as the typical value in the 1990. Many service technicians still recommend 3000 or 5000 miles service intervals in the conservative North American market, as it suits them as a source of revenue and also there is less of a need to provide top quality lubricants. Another trend of today represent midSAP (sulfated ash <0,8 wt.-%) and lowSAP (sulfated ash <0,5 wt.-%) engine oil (see specifications: MB 229.xx, MB 22x.x1, Renault RN 0720, FORD WSS-M2C934-A). The ACEA specifications C1 to C4 reflect the midSAP and lowSAP needs of automotive OEMs. Reason for this is that the small loss of the oil during engine life - that ends burned, exhaust valve stem cleanliness is improved and much less gypsum ends up plugging the catalyst and/or particulate filter. This improves emissions as the emission regulating system has longer service life then. It is much more remarkable in a trailer truck which can easily make 200000 to 400000 km every year. Furthermore, European ACEA standards require that during the long drain intervals of 30.000 km and up HTHS viscosity is maintained (High Temperature, High Shear) at around 3.5 cP (3.5 mPa·s). Required minimum HTHS viscosity is given by SAE oil grade. SAE 40 needs at least 3.5cSt, SAE 30 - 2.9cSt, etc. This is important when considering oil change in an engine. A too low HTHS viscosity and protection of piston rings and journal bearings may be compromised. Thus engines requiring SAE 0W-20 oil do so because their operating temperatures are far lower than those using SAE-40 viscosity oil. As in API, no system of marking that the product exceeds this critical specification by a significant amount is in place.

Because of the need for motor oils with unique qualities, many modern cars for the European market will demand a specific OEM-only oil standard. As a result, it may make no reference at all to ACEA or API standards. This is case of VW pumpe-düse diesel engines, as the manufacturer cannot guarantee longevity and reliability of a certain engine components without adherence to the specification. While it may be confusing that the standard may not specify SAE viscosity, it is not the important parameter. Wear protection and HTHS viscosity are important parameters and are not specified in the SAE viscosity standard. Additionally, API tests are performed on engines which suffer far lighter loads and shears. The reason for current development of new OEM standards is that in the 1970s to 1980s when the SAE and API refused to develop standards for characterising oils by their HTHS viscosity or by their lubricating properties, because 'some products would be looking bad even if they were completely OK'[15]

Quote from ASTM report on the matter: "The rapid growth of non-Newtonian multigraded oils has rendered kinematic viscosity as a nearly useless parameter for characterising "real" viscosity in critical zones of an engine. ...There are those who are disappointed that the twelve-year effort has not resulted in a redefinition of the SAE J300 Engine Oil Viscosity Classification document so as to express high-temperature viscosity of the various grades... ...In the view of this writer, this redefinition did not occur because the automotive lubricant market knows of no field failures unambiguously attributable to insufficient HTHS oil viscosity."[16] Since low and high quality oils conformed to the same standard which did not mandate critical parameters, engine manufacturers were FORCED to develop their own standards and tests, as the lubricant providers did NOT manufacture lubricants with guaranteed minimal lubricity under real world stress conditions at the time of the development of engines conforming to new legislation. As new lubricant standards were only always introduced after lenghty proceedings to arrive barely in time with the new generation of engines, users were always left in the dark when comparing various oil brands and products which all conformed to the same maximum specification, even if particular products could perform far better than others.

All this could be prevented 40 years ago when inclusion of HTHS standards was demanded by lubrication experts into any kind of standard.

Thus user today who wants to top up or change engine oil needs to pay close attention to the list of certificates on the oil label (on the back side), and gain understanding of the specific manufacturer designation meaning, which number signifies petrol engine, which diesel engine. Which number marks suitability for a turbocharged engine, etc.

Other additives

In addition to the viscosity index improvers, motor oil manufacturers often include other additives such as detergents and dispersants to help keep the engine clean by minimizing sludge buildup, corrosion inhibitors, and alkaline additives to neutralize acidic oxidation products of the oil. Most commercial oils have a minimal amount of zinc dialkyldithiophosphate as an anti-wear additive to protect contacting metal surfaces with zinc and other compounds in case of metal to metal contact. The quantity of zinc dialkyldithiophosphate is limited to minimize adverse effect on catalytic converters. Another aspect for after-treatment devices is the deposition of oil ash, which increases the exhaust back pressure and reduces fuel economy over time. The so-called "chemical box" limits today the concentrations of sulfur, ash and phosphorus (SAP).

There are other additives available commercially which can be added to the oil by the user for purported additional benefit. Some of these additives include:

- EP additives, like Zinc dialkyldithiophosphate (ZDDP) additives and sulfonates, preferably calcium sulfonates, are available to consumers for additional protection under extreme-pressure conditions or in heavy duty performance situations. Calcium sulfonates additives are also added to protect motor oil from oxidative breakdown and to prevent the formation of sludge and varnish deposits. Both were the main basis of additive packages used by lubricant manufacturers up until 1990's when the need for ashless addtitives arose. Main advantage was very low price and wide availability (sulfonates were originally waste byproducts). Currently there are ashless oil lubricants without these additives, which can only fulfill the qualities of the previous generation with more expensive basestock and more expensive organic or organometallic additive compounds. Some new oils are not formulated to provide the level of protection of previous generations to save manufacturing costs. Lately API specifications reflect that

- In the 1980s and 1990s, additives with suspended PTFE particles were available e.g. "Slick50" to consumers to increase motor oil's ability to coat and protect metal surfaces. There is controversy as to the actual effectiveness of these products as they can coagulate and clog the oil filters. It is supposed to work under boundary lubricating conditions, which good engine designs tend to avoid anyway. Also teflon alone has little to no ability to firmly stick on a sheared surface, unlike molybdenum disulfide, for example.

- Some molybdenum disulfide containing additives to lubricating oils are claimed to reduce friction, bond to metal, or have anti-wear properties. MoS2 particles can be shear-welded on steel surface and some engine components were even treated with MoS2 layer during manufacture, namely liners in engines. (Trabant for example)[17]. They were used in WWII in flight engines and became commercial after WWII until the 1990s. They were commercialized in the 1970s (ELF ANTAR Molygraphite) and are today still available (Liqui Moly MoS2 10 W-40, www.liqui-moly.de). Main disadvantage of molybdenum disulfide is antracite black color, so oil treated with is is hard to distinguish from a soot filled engine oil with metal shavings from spun crankshaft bearing.

- Various other extreme-pressure additives and antiwear additives.

- Many patents proposed use perfluoropolymers to reduce friction between metal parts, such as PTFE (Teflon), or micronized PTFE. However, the application obstacle of PTFE is insolubility in lubricant oils. Their application is questionable and depends mainly on the engine design - one that can not maintain reasonable lubricating conditions might benefit, while properly designed engine with oil film thick enough would not see any difference. Other invalid claim about PTFE is the friction factor as it depends on material hardness. PTFE is a very soft material, thus its friction coefficient becomes worse than that of hardened steel-to-steel mating surfaces under common loads. PTFE is used in composition of sliding bearings where it improves lubrication under relatively light load until the oil pressure builds up to full hydrodynamic lubricating conditions.

Synthetic oil and synthetic blends

Synthetic lubricants were first synthesized, or man-made, in significant quantities as replacements for mineral lubricants (and fuels) by German scientists in the late 1930s and early 1940s because of their lack of sufficient quantities of crude for their (primarily military) needs. A significant factor in its gain in popularity was the ability of synthetic-based lubricants to remain fluid in the sub-zero temperatures of the Eastern front in wintertime, temperatures which caused petroleum-based lubricants to solidify owing to their higher wax content. The use of synthetic lubricants widened through the 1950s and 1960s owing to a property at the other end of the temperature spectrum, the ability to lubricate aviation engines at temperatures that caused mineral-based lubricants to break down. In the mid 1970s, synthetic motor oils were formulated and commercially applied for the first time in automotive applications. The same SAE system for designating motor oil viscosityalso applies to synthetic oils.

Synthetic oils are derived from either Group III, Group IV, or some Group V bases. Synthetics include classes of lubricants like syntheticesters as well as "others" like GTL (Methane Gas-to-Liquid) (Group V) and polyalpha-olefins (Group IV). Higher purity and therefore better property control theoretically means synthetic oil has better mechanical properties at extremes of high and low temperatures. The molecules are made large and "soft" enough to retain good viscosity at higher temperatures, yet branched molecular structures interfere with solidification and therefore allow flow at lower temperatures. Thus, although the viscosity still decreases as temperature increases, these synthetic motor oils have a higher viscosity index over the traditional petroleum base. Their specially designed properties allow a wider temperature range at higher and lower temperatures and often include a lower pour point. With their improved viscosity index, synthetic oils need lower levels of viscosity index improvers, which are the oil components most vulnerable to thermal and mechanical degradation as the oil ages, and thus they do not degrade as quickly as traditional motor oils. However, they still fill up with particulate matter, although at a lower rate compared to conventional oils[citation needed], and the oil filter still fills and clogs up over time. So, periodic oil and filter changes should still be done with synthetic oil; but some synthetic oil suppliers suggest that the intervals between oil changes can be longer, sometimes as long as 16,000-24,000 km (10,000–15,000 mi) primarily due to reduced degradation by oxidation.

Tests[citation needed] show that fully synthetic oil is superior in extreme service conditions to conventional oil, and may perform better for longer under standard conditions. But in the vast majority of vehicle applications, mineral oil based lubricants, fortified with additives and with the benefit of over a century of development, continue to be the predominant lubricant for most internal combustion engine applications.

Bio-based oils

Bio-based oils existed prior to the development of petroleum-based oils in the 19th Century. They have become the subject of renewed interest with the advent of bio-fuels and the push for green products. The development of canola-based motor oils began in 1996 in order to pursue environmentally friendly products. Purdue University has funded a project to develop and test such oils. Test results indicate satisfactory performance from the oils tested.[18]

Maintenance

In engines, there is inevitably some exposure of the oil to products of internal combustion, and microscopic coke particles from black soot accumulate in the oil during operation. Also the rubbing of metal engine parts inevitably produces some microscopic metallic particles from the wearing of the surfaces. Such particles could circulate in the oil and grind against the part surfaces causing wear. The oil filter removes many of the particles and sludge, but eventually the oil filter can become clogged, if used for extremely long periods. The motor oil and especially the additives also undergo thermal and mechanical degradation. For these reasons, the oil and the oil filter need to be periodically replaced. While there is a full industry surrounding regular oil changes and maintenance, an oil change is a fairly simple operation that most car owners can do themselves.

Some vehicle manufacturers may specify which SAE viscosity grade of oil should be used, but different viscosity motor oil may perform better based on the operating environment. Many manufacturers have varying requirements and have designations for motor oil they require to be used. Some quick oil change shops recommended intervals of 5,000 km (3,000 mi) or every 3 months which is not necessary according to many automobile manufacturers. This has led to a campaign by the California EPA against the 3,000 mile myth, promoting vehicle manufacturer's recommendations for oil change intervals over those of the oil change industry.

Motor oil is changed on time in service or distance vehicle has traveled. Actual operating conditions and engine hours of operation are a more precise indicator of when to change motor oil. Also important is the quality of the oil used especially when synthetics are used (synthetics are more stable than conventional oils). Some manufacturers address this (i.e. BMW and VW with their respective long-live standards), while others do not. The viscosity can be adjusted for the ambient temperature change, thicker for summer heat and thinner for the winter cold. Lower viscosity oils are used in many newer American market vehicles. Time-based intervals account for the short trip driver who drives fewer miles, but builds up more contaminants. It is advised by manufacturers to not exceed their time or distance driven on a motor oil change interval. Many modern cars now list somewhat higher intervals for changing of oil and filter, with the constraint of "severe" service requiring more frequent changes with less-than ideal driving; this applies to short trips of under 16 km (10 mi), where the oil does not get to full operating temperature long enough to burn off condensation, excess fuel, and other contamination that leads to "sludge", "varnish", "acids", or other deposits. Many manufacturers have engine computer calculations to estimate the oil's condition based on the factors which degrade it such as RPMs, temperatures, and trip length; and one system adds an optical sensor for determining the clarity of the oil in the engine. These systems are commonly known as Oil Life Monitors or OLMs. In the 1960s typical cars took heavy 20W-50 oil[citation needed]. By the early 1980s recommended viscosities had moved down to 10W-30, primarily to improve fuel efficiency. A modern typical application would be Honda Motor's use of 5W-20 viscosity oil for 12,000 km (7,500 mi) while offering increased fuel efficiency. Engine designs are evolving to allow the use of low viscosity oils without the risk of high rates of metal to metal abrasion, principally in the cam and valve mechanism areas.

Future

A new process to break down polyethylene, a common plastic product found in many consumer containers, is used to make wax with the correct molecular properties for conversion into a lubricant, bypassing the expensive Fischer-Tropsch process. The plastic is melted and then pumped into a furnace. The heat of the furnace breaks down the molecular chains of polyethylene into wax. Finally, the wax is subjected to acatalytic process that alters the wax's molecular structure, leaving a clear oil. (Miller, et al., 2005)

Biodegradable Motor Oils based on esters or hydrocarbon-ester blends appeared in the 1990s followed by formulations beginning in 2000 which respond to the bio-no-tox-criteria of the European preparations directive (EC/1999/45).[19] This means, that they not only are biodegradable according to OECD 301x test methods, but also the aquatic toxicities (fish, algae, daphnie) are each above 100 mg/L.

Another class of base oils suited for engine oils represents the polyalkylene glycols. They offer zero-ash, bio-no-tox properties and lean burn characteristics.[20]

Re-refined motor oil

The oil in a motor oil product does not break down or burn as it is used in an engine—it simply gets contaminated with particles and chemicals that make it a less effective lubricant. Re-refining cleans the contaminants and used additives out of the dirty oil. From there, this clean “base stock” is blended with some virgin base stock and a new additives package to make a finished lubricant product that can be just as effective as lubricants made with all virgin oil.[21] The US Environmental Protection Agency defines re-refined products as containing at least 25% re-refined base stock,[22] but other standards are significantly higher. The California State public contract code define a re-refined motor oil as one that contains at least 70% re-refined base stock.[23]

Brands and manufacturers

| This article may contain excessive, poor or irrelevant examples. You can improve the articleby adding more descriptive text. See Wikipedia's guide to writing better articles for further suggestions. (September 2010) |

- 76 (Conoco Phillips)

- Aaron Motor Pty.Ltd

- ACDelco Lubricants

- Advanced Lubrication Specialties, Inc

- Agip

- Amalie

- Amsoil

- Bardahl

- Bel-Ray

- Bharat Petroleum

- BHPetrol

- BP (British Petroleum)

- Canadian Tire

- Castrol (BP)

- Cepsa

- Ceypetco

- Chevron

- Citgo

- Colorado Petroleum Products Company (Rugged/Silver State)

- Cross Oil Refining

- David Weber Oil Co.

- Delo (Chevron)

- Ekolube

- Elf

- Elofic Lubricants

- Engen

- Esso (outside U.S.)

- Exxon (U.S. only)

- Fuchs

- Galp Energia

- Green Earth Technologies

- Great wall (PetroChina)

- Gulf Oil

- Havoline (Texaco)

- Hindustan Petroleum

- Indian Oil Corporation

- Kendall (ConocoPhilips)

- Kunlun(Sinopec)

- Liqui Moly

- Liquoil

- Lubrication Engineers

- Lubriplate Lubricants

- Lucas Oil

- Mobil 1 (Mobil)

- Motorcraft

- Motul

- NEO

- Nulon

- Oando

- PEAK Motor Oil

- Pakelo

- Pakistan State Oil

- Pennzoil / Quaker State

- Penrite

- Pentosin

- Pertamina

- Per'tua

- Petro-Canada

- Petrobras

- Petronas

- Pinnacle Oil Co.

- Prestone

- Prolab Technologies

- Q8 (KPI)

- Red Line Oil

- Repsol

- Revtex (Caltex)

- Royal Dutch Shell (Shell Oil Company)

- Royal Purple

- Safety-Kleen Eco-Power(Re-Refined)

- Schaeffer Oil

- Sharlu

- Speedmaster

- Statoil Lubricants

- Sunoco (Advanced Lubrication Specialties, Inc)

- TexasTea Lubes

- Total S.A.

- Valvoline (Ashland Inc.)

- Voltrion oil (electrically treated oils Belgium)

- Warren Oil/Coastal/Unilube

- Warren Performance Products

- Wolf's Head

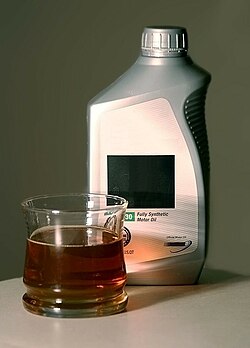

Packaging

| This section requires expansion. |

Motor oil came in cans, metal/cardboard cans, and glass bottles before the modern plastic bottle.

References

- ^ Klamman, Dieter, Lubricants and Related Products, Verlag Chemie, 1984, ISBN 0-89573-177-0

- ^ G. Corsico, L. Mattei, A. Roselli and C. Gommellini, Poly(internal olefins)- Synthetic Lubricants and high-performance functional fluids,, Marcel Dekker, 1999,Chapter 2, p. 53-62, ISBN 0-8247-0194-1

- ^ R.H. Schlosberg, J.W. Chu, G.A. Knudsen, E.N. Suciu and H.S. Aldrich, High stability esters for synthetic lubricant applications, Lubrication Engineering, February 2001, p. 21-26motor oil is bad for the environment.

- ^ "How Car Engines Work"

- ^ "Types of Lubricating Systems"

- ^ Chris Collins (2007), “Implementing Phytoremediation of Petroleum Hydrocarbons, Methods in Biotechnology' 23:99-108. Humana Press.ISBN 1588295419.

- ^ http://www.astm.org/Standards/D97.htm

- ^ Audizine - Audi oil reference - all you ever wanted to know

- ^ a b API Service Categories

- ^ ILSAC GF-4 Standard for Passenger Car Engine Oil - ILSAC

- ^ Development of the Sequence IIIG Engine Oil Test - ASTM Research Report

- ^ GF-4 Compliance

- ^ ILSAC GF-5 Standard for Passenger Car Engine Oil

- ^ Sticker placed on Mercedes Benz personal vehicles from at least 1991 onwards, specifying oil change intervals. For example MB W210 has one placed near hinge of the door of drivers side.

- ^ High-temperature, high-shear (HTHS) oil viscosity: measurement and ... By James A. Spearot, ASTM Committee D-2 on Petroleum Products,http://books.google.com/books?id=XjTaOqEgHeEC&printsec=frontcover#v=onepage&q&f=false

- ^ High-temperature, high-shear (HTHS) oil viscosity: measurement and ... By James A. Spearot, ASTM Committee D-2 on Petroleum Products,http://books.google.com/books?id=XjTaOqEgHeEC&printsec=frontcover#v=onepage&q&f=false

- ^ Trabant user maintenance manual, 1972

- ^ Canola-based Motor Oils - Purdue University

- ^ Directive 1999/45/EC of the European Parliament and of the Council concerning the approximation of the laws, regulations and administrative provisions of the member states relating to the classification, packaging and labelling of dangerous preparations, Official Journal of the European Communities L200/1, 30.07.1999, ISSN 0376-9461

- ^ M. Woydt, No /Low SAP and Alternative Engine Oil Development and Testing, Journal of ASTM International, 2007, Vol. 4, No.10, online ISSN 1546-962X or in ASTM STP 1501 “ Automotive Lubricants – Testing and Additive Development”, 03.-05. December 2006, Orlando, ISBN 978-0-8031-4505-4, eds.: Tung/Kinker/Woydt

- ^ http://fleetsuserro.org/what.htm

- ^ U.S. EPA Comprehensive Procurement Guidelines: Re-refined Lubricating Oilhttp://www.epa.gov/osw/conserve/tools/cpg/products/lubricat.htm

- ^ California State Contract Code 12209 http://law.onecle.com/california/public-contract/12209.html

External links

| Wikimedia Commons has media related to: Motor oil |

- How to change the oil in your car, a how-to article from wikiHow

- ACEA European Oil Sequences

- Table of SAE and ISO viscosity gradings

- A PDF table of motor oil technical specifications

No comments:

Post a Comment